Versatile Applications of Biomass Wood Boilers

Biomass wood boilers serve as sustainable energy solutions across numerous industrial sectors. These systems are particularly valuable for operations requiring substantial thermal energy while maintaining environmental responsibility. Many textile manufacturers utilize biomass wood boilers to generate steam for dyeing, drying, and finishing processes. Food processing plants commonly install these boilers for sterilization and cooking operations. Paper mills frequently employ biomass wood boilers to provide consistent heat for pulp treatment. District heating systems in colder climates are increasingly adopting biomass wood boilers due to their carbon-neutral operation.

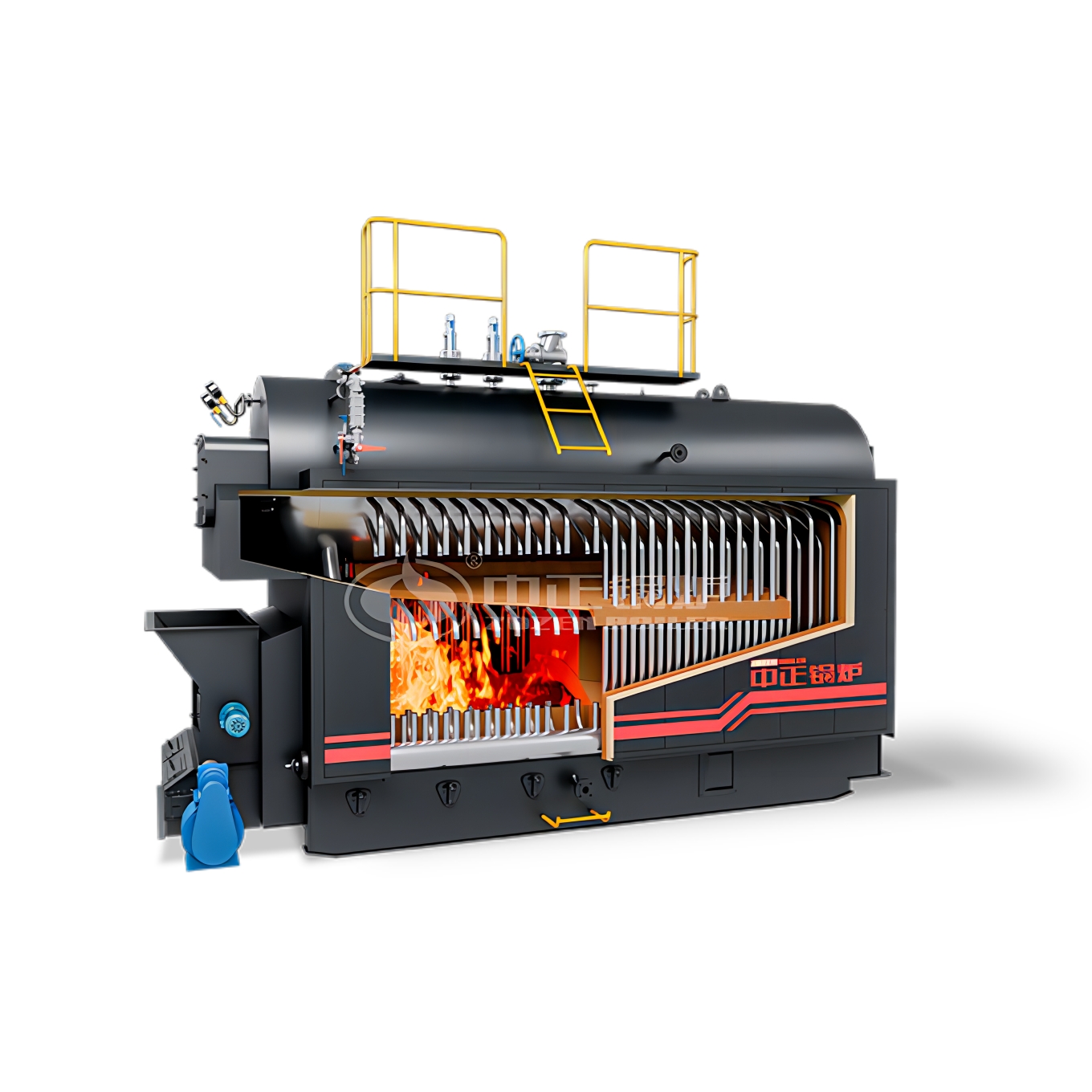

Distinctive Features of Modern Biomass Wood Boilers

Modern biomass wood boilers incorporate several advanced technological features that distinguish them from conventional heating systems. These units typically achieve high thermal efficiencies through carefully engineered combustion chambers. Manufacturers design these boilers to process diverse biomass materials with varying characteristics. Contemporary models integrate sophisticated control systems that automatically regulate operational parameters. Many units include self-cleaning mechanisms that significantly reduce maintenance requirements. Environmental performance remains a key consideration in their design and operation. The robust construction of these boilers ensures reliable performance.

ZOZEN’s Comprehensive Biomass Wood Boiler Solutions

ZOZEN Boiler offers three distinct series of biomass wood boilers, each designed to meet specific industrial requirements while maintaining high efficiency and reliability.

The SZL series represents ZOZEN’s water tube boiler solution for medium to large-scale operations. These boilers feature capacities ranging from 6 to 35 tons per hour with working pressures reaching 2.5 MPa. The SZL models incorporate a horizontal, double-drum design with chain grate stoker systems that ensure efficient fuel combustion. A key characteristic of this series is its membrane water-cooled wall construction, which significantly enhances heat transfer efficiency while protecting the furnace structure. The SZL series demonstrates particular strength in handling various biomass fuels, while maintaining thermal efficiency above 86%.

ZOZEN also developed the DZL series quick-installed boiler. These units provide steam outputs between 2 to 10 tons per hour at working pressures up to 2.5 MPa. The DZL series stands out for its compact three-pass design that combines space efficiency with straightforward installation. These boilers employ automatic feeding systems and specially engineered smoke tube bundles that optimize heat exchange performance. The combustion chamber ensures complete fuel burnout while minimizing harmful emissions, with thermal efficiency consistently reaching 83%. The series offers particular advantages for operations requiring reliable steam supply in limited spaces.

ZOZEN DZL Series Biomass Wood Boiler

For large-scale industrial applications, ZOZEN offers the DHL series boilers with substantial capacity ranges. These high-performance units provide 20 to 75 tons per hour at working pressures reaching 5.3 MPa. The DHL series features a unique structural design combined with grate systems that ensure stable combustion across different biomass fuel types. With thermal efficiency reaching 86.8%, these boilers represent ZOZEN’s most advanced solution for continuous, high-demand operations. The series incorporates sophisticated combustion control systems and is engineered to withstand the rigorous demands of large industrial facilities while maintaining exceptional environmental performance.

Operational Advantages Demonstrated in Textile Application

ZOZEN’s biomass wood boilers deliver significant benefits across various industries, as evidenced by recent installations. A prominent textile manufacturer in Pakistan implemented a 25-ton biomass steam boiler solution. The installation incorporated hydraulic reciprocating grate technology. Custom engineering solutions optimized the furnace geometry for enhanced heat transfer. The system achieved remarkable thermal efficiency while maintaining consistent steam output. Operational benefits included substantial reductions in fuel costs and labor requirements. The boiler system helped the manufacturer meet stringent environmental regulations. Production efficiency improvements and energy savings became immediately apparent after commissioning.

Conclusion: The Future of Industrial Heating

Biomass wood boilers represent a sustainable solution for industrial heating requirements. These systems effectively bridge the gap between energy needs and environmental responsibility. Modern designs incorporate advanced combustion technology and automated control systems. The robust construction of these boilers ensures long-term reliable operation. Increasing global emphasis on carbon reduction favors wider adoption of these systems. Continuous innovation in boiler technology addresses evolving efficiency requirements. Industries seeking to reduce environmental impact find these solutions increasingly attractive. Biomass wood boilers offer a practical path toward sustainable industrial operations. Their role in global energy strategies will likely expand in coming years.

.png)