| Product thermal capacity: | 7-116 MW |

| Working pressure: | 1.0-1.6 Mpa |

| Available fuel: | Nature gas, coke oven gas, blast furnace gas, carbon black off-gas, biogas, methanol, LPG, diesel, heavy oil, light oil, crude oil, etc. |

| Available industries: | Heat supplying, hospital, colleges and universities. |

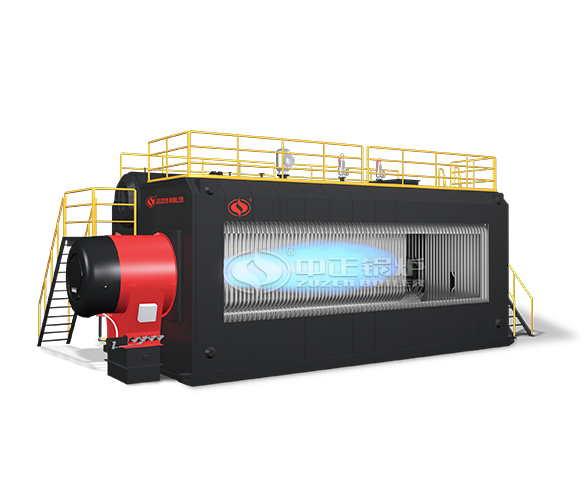

Introduction of SZS series gas-fired(oil-fired) hot water boiler

SZS boiler body is the structure of longitudinal double drums and D-type chamber combustion. The furnace is on right side and the convection tube bundle are on left side. The flexible supports of boiler are in the middle and two ends of the lower drum, and it can secure the whole boiler body to expand sideways. There are narrow-space membrane cooling tube walls on the four sides of furnace. The left membrane wall makes the furnace and the convection tube bundle separated. The rear of convection tube bundle is a kind of tube-decreasing and staggered structure, and the front is an aligned structure. The flue gas generated from furnace combustion flows from the rear outlet of furnace into the end of combustion chamber, convection tube bundle area, and then turns from the front-left of furnace to the spiral finned tube economizer, and next flows into smoke duct and chimney and finally exhausts into atmosphere.

Features of SZS series gas-fired(oil-fired) hot water boiler

1. Boiler body uses the forced circulation in the high temperature area to make sure all heating areas can be cooled down and avoid vaporization; The explosion door and flame detector are equipped for safe and reliable operation. Comb plates are used between both sides of boiler and tube bundle to avoid leakage of condensate and gas caused by using refractory concrete as sealing material.

2. Big combustion chamber equipped with Low emission combustion burner effectively reduce the NOx to 30mg/m3. Smoke duct and smoke outlet use internal insulation to reduce operating noise.

3. Good quality alumina silicate fiber and fire clay insulation material are used and the boiler body temperature is controlled below 45℃ and greatly heat loss is reduced. Combustion chamber is designed with narrow distance tube membrane water cooling wall which has good air proof to reduce heat lost and increase boiler thermal efficiency.

4. Manholes are placed on the front and back side of drums and inspection doors on back side of boiler easy to open for inspection and clean inner and outer parts.

SZS series gas-fired(oil-fired) hot water boiler price

About how to choose the boiler, you need to consider the following aspects: rated thermal power, rated working pressure, rated output water temperature,rated feeding water temperature, etc.You can choose the proper crusher type according to your needs and requirements.

If you are new in this industry,we will provide professional suggestions and solutions for you.

About SZS series gas-fired(oil-fired) hot water boiler price, we will provide China 100% factory price and maxmium discount for you.