Coal boilers remain a critical component in many industrial energy systems, particularly in regions where coal is an abundant and cost-effective fuel source. There are several coal boiler types, each designed to meet specific operational needs, fuel characteristics, and environmental requirements. The most common coal boiler types include chain grate boilers, circulating fluidized bed (CFB) boilers and so on.

These various coal boiler types offer flexibility in fuel use, efficiency, and environmental performance, allowing enterprises to choose the most suitable option based on their specific needs and resource availability.

Industrial Applications of Coal Boiler Types

The diversity of coal boiler types enables their application across a wide range of industries. In the textile industry, coal boilers provide the necessary steam for dyeing, drying, and fabric processing. In the chemical industry, they are used to power reactors, distillation units, and other production equipment. The food and beverage industry also relies on coal boilers for cooking, sterilization, and drying processes.

In developing countries, where coal remains a primary energy source, coal boiler types are especially prevalent in sectors such as building materials, paper manufacturing, metallurgy, and agriculture. For example, in the cement and brick industries, coal boilers generate the high-temperature steam needed for curing and processing. In paper mills, they are used to produce steam for pulping and drying.

The adaptability of different coal boiler types to various coal grades and industrial needs makes them an indispensable part of energy infrastructure, particularly in areas where alternative fuels are less accessible or more expensive.

Parameters and Features of ZOZEN Boiler’s DHL, DZL, SZL and DHX Series

ZOZEN Boiler offers a comprehensive range of coal boiler types, including the DHL, DZL, SZL and DHX series. Each of these series is engineered to deliver high performance, fuel efficiency, and operational reliability.

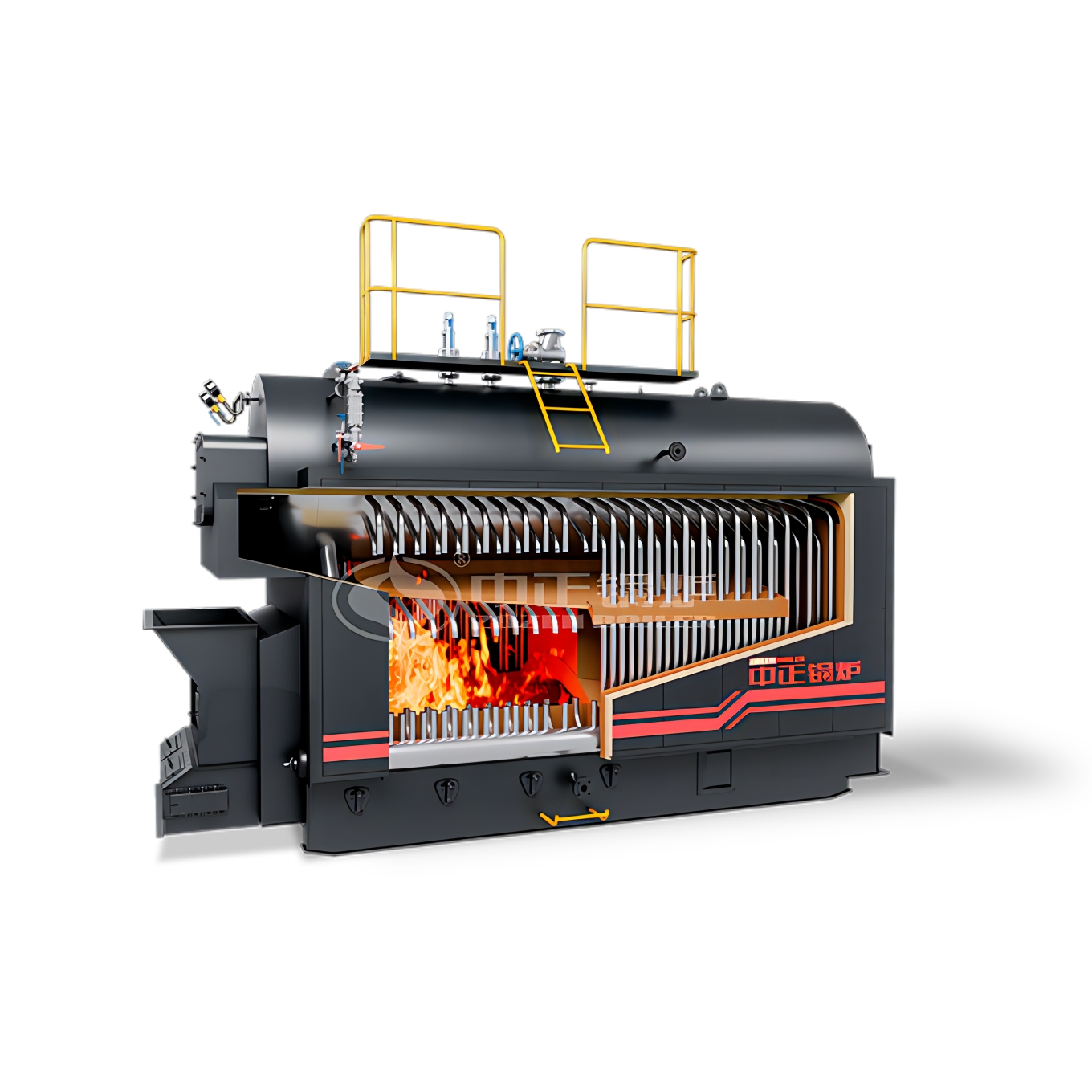

The DHL series is a corner tube chain grate boiler. It features a fully enclosed membrane wall structure, high automation, and advanced combustion technology. The DHL boiler supports capacities up to 75 tons per hour and offers excellent fuel adaptability and emission control.

The DZL series is a single-drum, horizontal chain grate boiler. Available in capacities ranging from 2 to 10 tons per hour, it is equipped with threaded smoke tubes that enhance heat transfer. The DZL boiler achieves thermal efficiency above 83% and is capable of burning various coal types, including bituminous coal and anthracite.

ZOZEN DZL Coal Boiler

The SZL series is a double-drum, vertically arranged water tube boiler. It is suitable for medium to large industrial applications, with steam output ranging from 6 to 35 tons per hour. The SZL boiler ensures complete combustion and high thermal efficiency over 81%. It also supports automatic feeding, ash removal, and slag discharge, making it easy to operate and maintain.

ZOZEN’s DHX series boiler is a circulating fluidized bed (CFB) boiler designed for high efficiency and fuel flexibility. It features a thermal efficiency of over 88%, significantly reducing fuel consumption and operating costs. The boiler adopts low-temperature combustion technology, effectively suppressing NOx emissions to meet environmental standards. With a wide fuel adaptability, it can burn various fuels, including coal, biomass and sludge. It offers capacities ranging from 20 to 75 t/h, making it ideal for medium-to-large-scale enterprises.

Each of these coal boiler types from ZOZEN Boiler is designed to meet the demanding needs of modern industries while ensuring compliance with environmental standards and maintaining a competitive cost-performance ratio.

Case Study: Coal Boiler Application in the Pet Supplies Industry

The growing pet economy has driven the expansion of the pet supplies manufacturing industry, particularly in emerging markets like Cambodia. In such regions, coal remains a dominant fuel source due to its affordability and accessibility. Therefore, the flexibility and fuel adaptability of different coal boiler types became a critical consideration in equipment selection.

A recent project involved ZOZEN Boiler providing a 4-ton DZL series coal-fired steam boiler to a pet supplies enterprise in Cambodia. This boiler was selected for its high thermal efficiency and excellent adaptability to different coal grades. The DZL series boiler utilizes threaded smoke tubes to enhance heat transfer, allowing it to achieve a thermal efficiency of over 80%. This significantly reduced the company’s fuel costs.

Moreover, the boiler demonstrated strong adaptability to a range of coal types, including bituminous coal, lean coal, and anthracite. This feature is particularly beneficial in Cambodia, where coal quality can vary significantly. The ability to efficiently burn different coals ensures consistent performance and energy savings, even when fuel sources fluctuate.

This case highlights the practical advantages of ZOZEN’s coal boiler types, especially in fuel-flexible and cost-sensitive markets. The boiler’s automation features also contributed to reducing labor intensity and improving operational safety.

Conclusion

In conclusion, the variety of coal boiler types provides industries with flexible and efficient options for generating steam and thermal energy. These boilers are essential in many sectors, particularly in developing regions where coal remains a primary energy resource.

ZOZEN Boiler stands out in the industry with its DHL, DZL, SZL and DHX series, offering robust performance, superior fuel adaptability, and high thermal efficiency. These coal boiler types are designed to meet diverse industrial requirements while ensuring cost-effectiveness and environmental compliance.

Through real-world applications such as the pet supplies industry case in Cambodia, ZOZEN has demonstrated the reliability and adaptability of its coal boiler types in various operating conditions. Whether addressing fuel variability or meeting growing energy demands, ZOZEN’s solutions continue to deliver value and performance, making them a trusted choice in the global industrial boiler market.