Introduction to Circulating Fluidized Bed Combustion Boiler

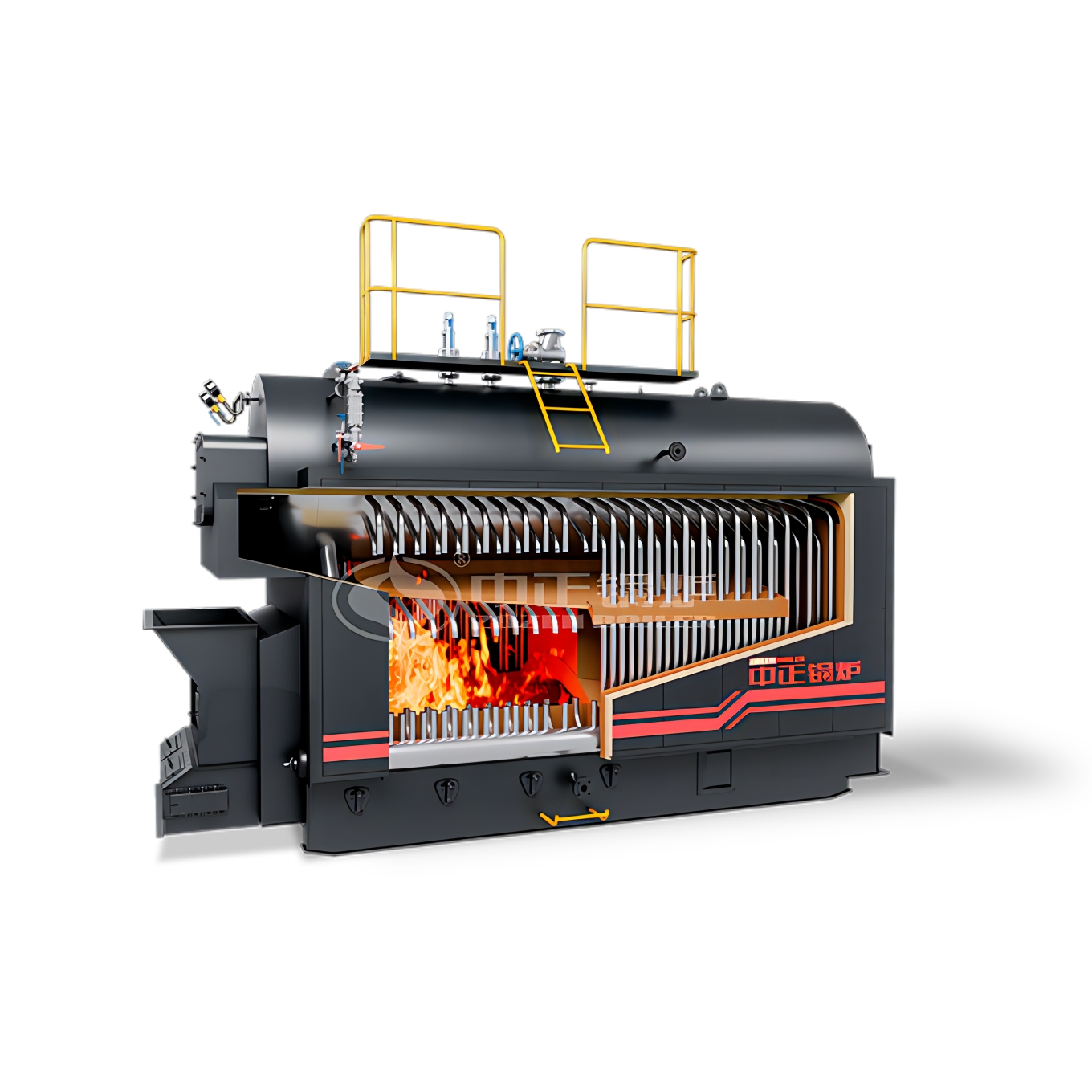

A circulating fluidized bed combustion boiler (CFBC boiler) is an advanced combustion technology that offers high efficiency and low emissions in power generation and industrial heating. Unlike traditional coal boilers, the CFBC boiler circulates a mixture of fuel, air, and inert materials like sand or ash in a fluidized state during combustion. This system promotes thorough mixing and extended residence time of particles, leading to complete combustion of fuel at lower temperatures.

The circulating fluidized bed combustion boiler stands out for its adaptability to various fuel types, energy efficiency, and environmentally friendly operation which makes it an attractive solution for countries and regions relying heavily on coal or biomass. As environmental regulations become more stringent, industries are increasingly turning to CFBC technology for sustainable, large-scale energy production.

Unique Features of Circulating Fluidized Bed Combustion Boiler

One of the defining characteristics of a circulating fluidized bed combustion boiler is its fuel flexibility. It can burn a wide range of fuels, including coal, biomass, sludge, petroleum coke, and even industrial waste. This makes it a highly adaptable system that can be tailored to local resource availability, reducing dependency on imported fuels and optimizing operational costs.

Additionally, CFBC boilers are known for their low combustion temperature. This feature significantly reduces the formation of nitrogen oxides (NOx), a major pollutant in traditional high-temperature combustion systems. The in-bed desulfurization process, commonly achieved by adding limestone, results in sulfur dioxide (SO₂) emissions being captured directly during combustion. Consequently, circulating fluidized bed combustion boilers can achieve both low NOx and low SO₂ emissions without the need for expensive post-combustion treatment systems.

Another advantage is the high thermal efficiency and stable output of CFBC boilers. The continuous circulation of bed material ensures even heat distribution and consistent temperature control, which is critical for both power generation and industrial applications.

ZOZEN Boiler’s SHX Series: A Case Study in Mongolia

ZOZEN Boiler has been at the forefront of CFBC technology, delivering tailored solutions that meet the specific needs of diverse clients. One significant project involved providing a circulating fluidized bed combustion boiler to a local heating initiative in Mongolia. ZOZEN supplied its SHX series 7 MW coal-fired hot water boiler, designed to operate efficiently under the region’s challenging conditions.

In this project, ZOZEN Boiler designed a customized solution based on the client’s operational requirements and Mongolia’s environmental and resource characteristics. The SHX series boiler was engineered to support multiple fuel types, including coal, gangue, biomass, industrial waste, and sludge. This capability was vital due to Mongolia’s rich coal reserves and the need for flexibility in energy sourcing.

The SHX series circulating fluidized bed combustion boiler achieves low emissions. By using in-furnace desulfurization and precise air staging, the boiler maintains nitrogen oxide emissions below 100 mg/Nm³. This level of performance not only helps reduce environmental impact but also ensures compliance with increasingly strict environmental regulations.

Technical Specifications and Advantages of ZOZEN’s SHX Series Circulating Fluidized Bed Boilers

ZOZEN Boiler’s SHX series represents a high-performance line of circulating fluidized bed combustion boilers. These advanced systems combine robust engineering with environmental consciousness to deliver superior operational performance. SHX series Circulating Fluidized Bed Boilers’ thermal capacity ranges from 10 to 35t/h. It can work under pressure up to 2.5 MPa with thermal efficiency over 88%.

ZOZEN SHX Series Circulating Fluidized Bed Combustion Boiler

A standout feature is its exceptional fuel flexibility, capable of efficiently burning diverse fuels including coal, biomass, sludge, and various industrial waste materials. This versatility ensures reliable operation across different industrial scenarios and fuel availability conditions.

Environmental performance is a key strength of the SHX series. The system incorporates in-furnace desulfurization technology, resulting in significantly reduced pollutant emissions. The optimized fluidized bed design achieves high combustion efficiency by ensuring complete burning of fuel particles. Advanced control systems coupled with continuous circulation of bed materials guarantee stable operation with consistent heat output and minimal performance fluctuations. These engineering solutions enable the boilers to consistently maintain SO₂ and NOx emissions well within stringent international environmental standards.

Beyond its technical excellence, ZOZEN Boiler provides comprehensive project support throughout the entire system lifecycle. The company’s engineering and service teams delivered complete solutions encompassing design, installation, and commissioning services. Even when facing Mongolia’s extreme winter conditions and complex logistical challenges, ZOZEN’s technical expertise and responsive service ensured the project’s successful and timely completion. This combination of advanced technology and reliable support makes the SHX series an ideal solution for industrial operations seeking efficient, environmentally compliant thermal solutions.

Conclusion: Sustainable Heating with Circulating Fluidized Bed Combustion Boiler

The circulating fluidized bed combustion boiler provides a new, efficient, and low-pollution clean coal method in the field of industry. Its ability to burn various fuels efficiently, reduce harmful emissions, and maintain reliable operation makes it a preferred choice for sustainable energy solutions. As environmental pressures and fuel diversity increase, CFBC technology offers a path forward for industries aiming to reduce their carbon footprint without compromising performance.

ZOZEN Boiler’s SHX series exemplifies the benefits of this advanced technology. Through innovative engineering, flexible design, and professional execution, ZOZEN delivers value that goes beyond the boiler itself. The successful implementation of the Mongolian heating project is a testament to how circulating fluidized bed combustion boilers can provide reliable, clean, and cost-effective energy—even in the most demanding environments.

As industries worldwide seek smarter, greener ways to meet their energy needs, ZOZEN Boiler continues to lead the way with advanced circulating fluidized bed combustion boiler solutions that combine performance, efficiency, and environmental responsibility.