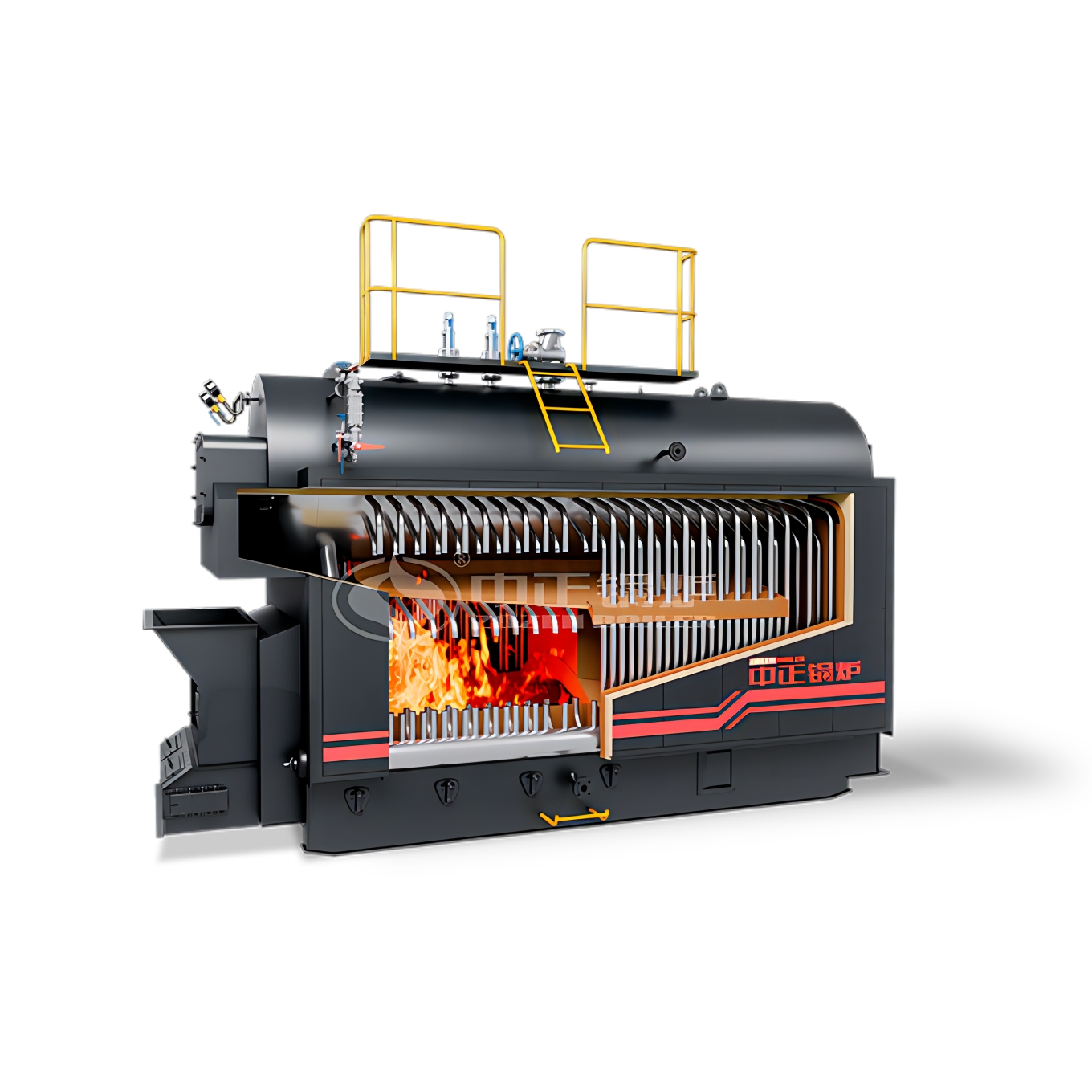

Chain Grate Coal Boiler Working principle:

Chain grate coal fired boiler is one of the most widely used mechanized combustion equipment in industrial boilers, but it has a certain range of coal adaptability. The combustion mode of chain grate boiler is mobile fire bed combustion, and the fuel ignition condition is “limited fire”. The fuel enters the grate through the coal hopper, and with the movement of the grate, the combustion process starts from the inside of the grate, and the burnt cinder is discharged to the slag well at the end of the grate with the movement of the grate. Therefore, compared with reciprocating furnace, vibration furnace and rimming furnace, chain grate boiler has higher requirements on coal grade. Mechanical coal thrower is basically a layer fire grate with infinite ignition and its adaptability to coal quality is relatively wide.

Its working principle is the chain grate is driven by the reducer to rotate, so that the coal is ignited from the front to the end of the boiler, which can improve the combustion efficiency compared with the fixed grate. At the same time, when the chain is rotated to the bottom, the air cooling can protect the grate plate from burning out, which is a better combustion equipment in the layer burner.

Due to the fluctuation of coal quality, coupled with boiler body design, operation level of boiler operators, ash accumulation and other reasons, the average operating efficiency of the actual layer combustion boiler is around 70%. It is estimated that the power consumption of coal-fired boilers, slag removal and dust removal water consumption, labor, maintenance accessories and other costs converted cost of about 20 yuan/ton of steam.

Advantages and disadvantages

Advantages of Coal Fired Boiler:

Coal as fuel supply is guaranteed, and the boiler technology is mature, the familiar degree of the stoker is high, the use cost is lower than the biomass fuel.

Disadvantages of Coal Fired Boiler:

1.Large space is occupied by ancillary facilities such as coal-fired boiler room, coal-storage shed and coal-unloading device;

2.The pressure from environmental protection and emission reduction has forced small and medium-sized industrial boilers to withdraw from the status of being dominated by coal and other fossil fuels, and the treatment cost of “three wastes” has increased significantly.

Chain grate coal fired boiler is especially suitable for countries and regions with unstable gas source, no good alternative fuel or low emission requirement. ZOZEN boiler has been engaged in industrial boiler production for more than 30 years and has rich experience. Now, our main products include gas boilers, biomass boilers, coal-fired boilers, thermal oil boilers and other more than 400 varieties of specifications, and widely used in chemical, food, brewing, heating, paper, printing and dyeing, rubber and other industries. Through our efforts, ZOZEN boiler has been exported to more than 100 countries and regions. To better serve our customers, we have offices in many countries and we are still recruiting boiler agents!

ZOZEN boiler has been unanimously approved by users. We also take “make the product that you want, make you and your business more dynamic” as our mission. To provide customers with more valuable high-tech boilers! If you want to buy boiler, you might as well contact us, maybe you will get unexpected benefits.

For detailed boiler quotes, you can consult online customer service or email me lexie@zozen.com.