Textile Industry 4 ton Biomass-fired Steam Boiler Introduction

Through the comparison and investigation of major boiler brands in the market, the purchasing manager of a textile factory finally chose ZOZEN Boiler as the supplier of 4 ton biomass fired steam boiler for their company. ZOZEN design team customized a 4 ton per hour steam boiler system according to the actual gas consumption of the customer’s production process, which is fully capable of meeting the daily use of the textile factory production line.

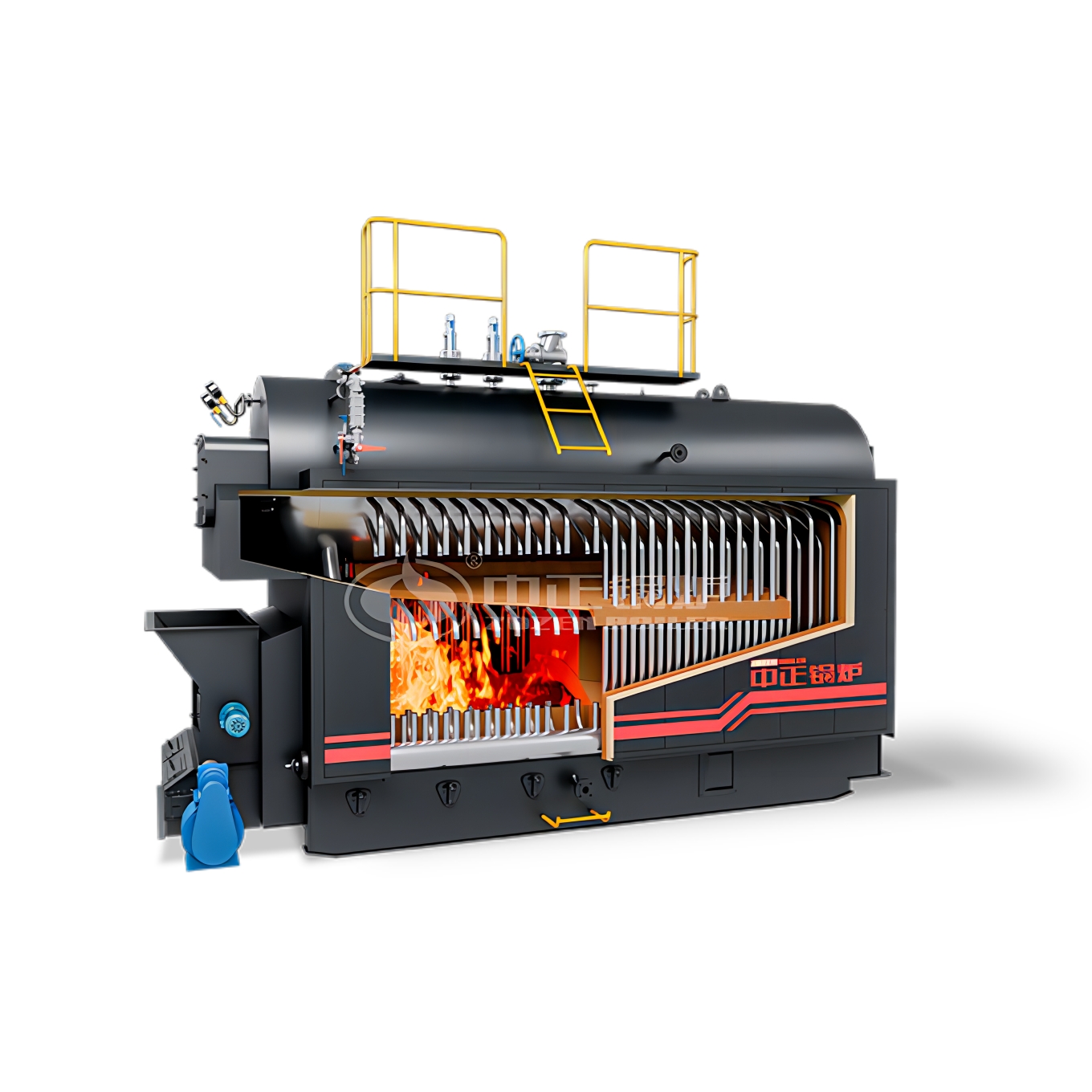

4 ton Biomass-fired Steam Boiler

ZOZEN DZL series biomass fired boiler is a horizontal three-pass water fire tube chain grate boiler. The DZL biomass steam boiler can use biomass pellets, rice husk, wood chips, corn cob, straw, palm husk and other fuels, while matching the appropriate grate to different fuel characteristics. This 4 ton biomass steam boiler has reasonable arrangement of furnace arch, furnace wall and furnace heating surface, adopts threaded flue tube high efficiency heat transfer element, equipped with advanced burner to ensure full combustion of fuel, improve heat transfer effect and ensure the boiler thermal efficiency reaches over 88%.

This DZL series biomass steam boiler is equipped with advanced steam-water separation device, which effectively separates steam and water and ensures the quality of steam. The unique design structure of this type of boiler ensures complete combustion of fuel. 4 tons steam boiler adopts quick-assembly structure and is shipped directly after the manufacturing is completed at the factory. ZOZEN arranges factory production immediately after signing the contract with the customer to ensure that the boiler is delivered to the customer within the agreed deadline.

Customer feedback

The ZOZEN biomass steam boiler is currently operating stably in our textile mill, where it provides a continuous supply of sufficient steam for our textile production process.

.png)